1. Stunning Equipment

Stunning equipment is employed to render the poultry unconscious before processing, minimizing stress and pain for the animals. Common types of stunning equipment include:

- Electrical Water Bath Stunning: The poultry is immersed in a water bath through which an electric current passes, inducing instantaneous unconsciousness.

- Controlled Atmosphere Stunning (CAS): Birds are exposed to carefully controlled gas mixtures, causing unconsciousness without the need for physical restraint.

2. Killing Equipment

The killing process is essential to ensure humane slaughter. Common methods include:

- Mechanical Neck Cutting Machine: This machine quickly and accurately severs the carotid arteries and jugular veins to induce a rapid loss of blood, leading to unconsciousness and death.

- CO2 Stunning/Killing: Birds are exposed to a high concentration of carbon dioxide, inducing unconsciousness and ultimately leading to death

3. Scalding Equipment

Scalding is a crucial step in feather removal. The equipment includes:

- Scalding Tanks: These tanks maintain a controlled temperature and water flow to loosen feathers for easier plucking.

4. Plucking

Plucking machines help remove feathers efficiently, ensuring cleanliness and minimizing damage to the bird’s skin. Types of plucking equipment include:

- Rotary Drum Plucker: Birds are passed through a rotating drum with rubber fingers that remove feathers gently.

- Wet Plucking Machine: This equipment uses high-pressure water jets to strip off feathers.

5. Evisceration Equipment

Evisceration involves the removal of internal organs. Equipment used in this process includes:

- Evisceration Line: A series of machines such as vent cutters, neck cutters, and gutters automate the removal of organs.

- Automatic Gut Separation Systems: These machines separate the edible intestines from the inedible parts.

6. Chilling Equipment

Chilling equipment is crucial for maintaining the meat’s quality and safety by reducing bacterial growth. Types of chilling equipment include:

- Water Chillers: Carcasses are immersed in cold water to lower their temperature rapidly.

- Air Chillers: Cold air is circulated around the carcasses to chill them.

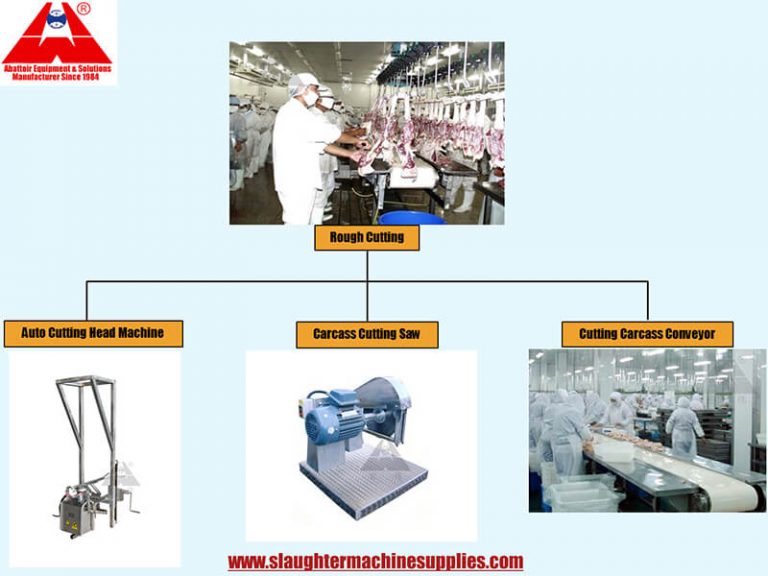

7. Cut-up and Deboning Equipment

This equipment is responsible for dividing the carcasses into various cuts and deboning the meat. Examples include:

- Cut-up Lines: Automated systems cut the carcasses into desired parts like breasts, wings, thighs, and drumsticks.

- Deboning Machines: These machines separate meat from bones with precision.

8. Inspection and Quality Control Equipment

Quality control is crucial to ensure safe and wholesome products. Equipment includes:

- X-ray Machines: These detect foreign objects like bone fragments in the meat.

- Metal Detectors: Used to identify metal contaminants in the final product.

If you want more information, please contact us by email or WhatsApp. You can add our WhatsApp by scanning the QR code on the right.

Would want to purchase a chicken slaughtering and processing plant.

My capacity is 150 000 per cycle