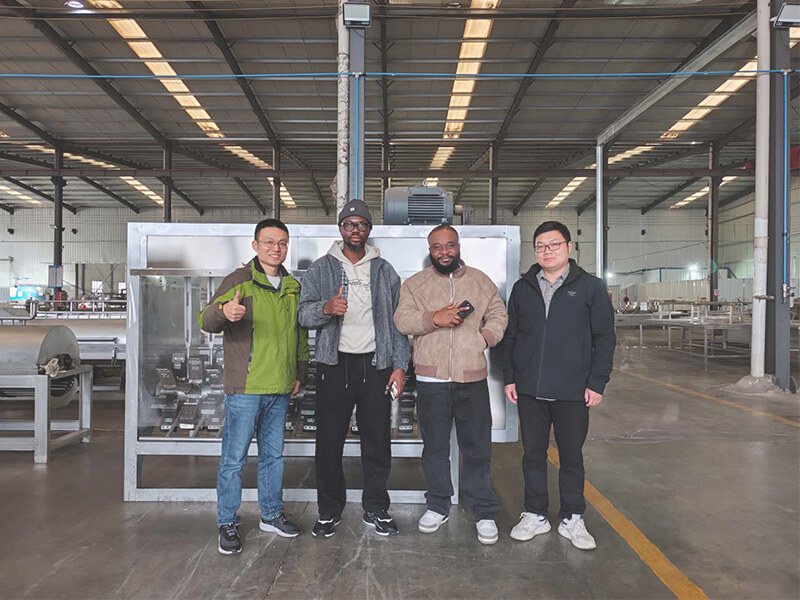

On Saturday, November 15, 2025, HW Machinery welcomed our clients from Ghana to our manufacturing base to check pig slaughter line & hog abattoir equipment for an in-depth factory tour, technical discussions, and project planning for a small-scale pig slaughter line (10–20 pigs/day).

HW Machinery — is China’s leading manufacturer of pig, cattle, sheep, poultry/chicken abattoir equipment, slaughter line machinery, meat processing equipment, and cleaning equipment.

⭐ Customer Requirements: 10–20 Pigs Per Day

During the meeting, the Ghanaian clients explained their project needs:

Daily slaughtering capacity: 10–20 pigs/day

Priority: Low initial investment, simple operation, easy maintenance

Goal: A practical, efficient, small-scale pork processing workflow

Based on these requirements, HW Machinery provided a cost-effective mini pig slaughter line solution, including essential pig slaughterhouse equipment:

✔ Recommended equipment (core small-scale solution)

Pig stunner

Transport cart

Electric scalding tank

Pig dehairing machine

Electric hoist

Pork carcass splitting saw

Small sectioning saw

Slaughter hooks

⭐ On-Site Demonstration of the Complete Pig Slaughter Process

Our clients inspected nearly all related pig slaughter machines during the visit. Our engineers demonstrated the full workflow using the recommended equipment:

1. Stunning

Using a pig stunner to humanely stun the pig.

2. Bleeding

Manual sticking and bleeding.

3. Scalding

Using a transport cart to move the carcass to the electric scalding tank, where water is heated to 60–65°C.

4. Dehairing

When hair is easily removable by hand, the pig is lifted via the fork of the pig dehairing machine.

Within 1–2 minutes, the dehairing process finishes.

5. Hoisting

Using electric hoist and hooks to lift the carcass for evisceration.

6. Splitting

Using a carcass splitting saw to split the hog into halves.

7. Sectioning

Operators place the carcass on the sectioning saw worktable for cutting into commercial pork parts.

This streamlined workflow is simple, efficient, and easy for small slaughterhouses to operate, even with limited manpower.

The Ghanaian clients were extremely satisfied, requested immediate on-site quotation, and confirmed that they will arrange payment right after returning home.

🔧 About HW Machinery

Established in 1984, HW Machinery operates three specialized manufacturing bases:

🟦 Base 1

Poultry/chicken slaughter machines & processing equipment

🟩 Base 2

Pig, cattle, and sheep slaughtering equipment & complete abattoir solutions

🟧 Base 3

Crate washing & drying machines, meat & sausage processing equipment, food machinery, and cleaning equipment

We deliver:

✔ Turnkey slaughter lines

✔ Meat processing equipment

✔ Project design, installation, training, and after-sales service

✔ Solutions for farms, slaughterhouses, abattoirs, meat factories, food plants, and international buyers

HW Machinery is dedicated to helping the global meat industry achieve: Food safety, Hygiene, Efficiency, Humane slaughter, Sustainable food supply.

📞 Contact HW Machinery

WhatsApp: +86 181 3678 1121 | +86 181 1589 1680

Email: [email protected] | [email protected]

Websites:

www.slaughtermachinesupplies.com

www.hwfoodmachinery.com

www.hongweislaughterline.com

HW Machinery — Your Partner in Food Processing & Slaughter Solutions.