Introduction

The cattle slaughtering industry has evolved significantly over the years, shifting from traditional, manual methods to advanced, automated systems. Today, modern cattle slaughtering machinery plays a critical role in ensuring efficiency, improving meat quality, and maintaining the highest standards of animal welfare. The integration of cutting-edge technologies has not only enhanced productivity but has also ensured compliance with global regulations. This evolution marks a transformative phase in the industry, prioritizing humane practices and hygiene without compromising operational efficiency.

Modern Cattle Slaughtering Machinery

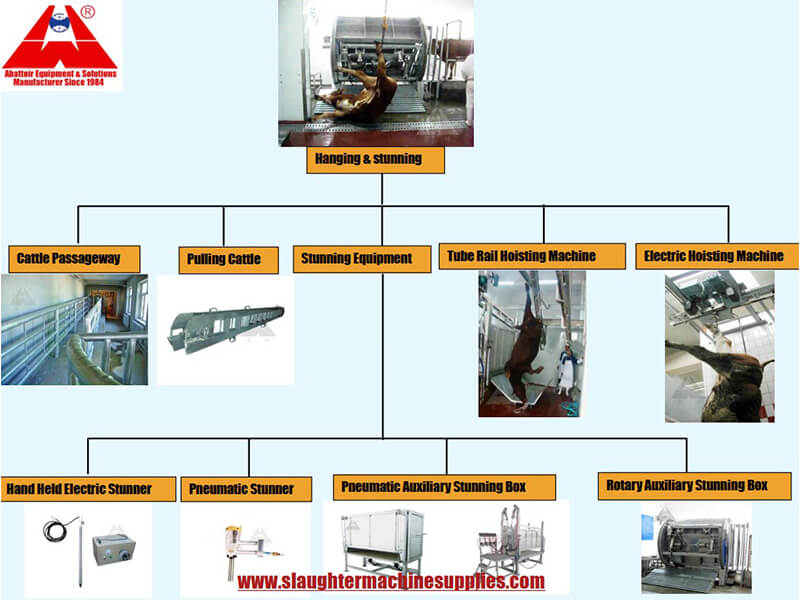

Modern cattle slaughtering machinery has revolutionized the meat processing sector, streamlining various stages of the slaughtering process. From stunning to carcass cutting, today’s equipment is designed to optimize productivity and reduce manual labor. Automated systems ensure precise cuts, efficient bloodletting, and rapid carcass processing, minimizing the risk of contamination and ensuring uniformity. Additionally, these machines are built to meet strict hygiene requirements, featuring stainless steel components that are easy to clean and maintain, thus reducing downtime between cycles.

Advanced cattle abattoir equipment is engineered to handle large volumes while maintaining the highest quality standards. With innovations like hydraulic dehiders and scalding tanks with automated temperature controls, slaughterhouses can achieve faster processing times while upholding meat quality and safety.

Automation and Efficiency

One of the most significant advantages of modern cattle slaughtering machinery is the high level of automation it offers. Automated systems help slaughterhouses maintain consistent quality, even when handling large-scale operations. For instance, automated stunning systems ensure humane treatment of cattle while significantly reducing the time required for each stage of the process. Moreover, equipment like conveyor systems, carcass splitters, and automated bloodletting devices help reduce labor costs by minimizing the need for manual intervention.

This automation also enhances safety within the facility. By reducing direct human interaction with the machinery, risks of accidents are minimized, making for a safer working environment. Overall, the automation incorporated into modern cattle abattoir equipment contributes to higher throughput, consistency in meat processing, and reduced operational costs.

Animal Welfare and Hygiene

Modern cattle slaughter lines are designed with a strong focus on animal welfare and hygiene. These systems follow strict global animal welfare guidelines, ensuring that cattle experience minimal stress during the slaughtering process. Equipment like anti-slip raceways, humane stunning systems, and temperature-controlled scalding tanks all contribute to creating a more humane and efficient process.

From a hygiene standpoint, modern cattle slaughtering machinery is equipped with automated cleaning features and built-in stainless steel construction, making it easy to clean and sanitize between production cycles. This reduces the risk of contamination, ensuring that meat products meet high safety standards and are free from harmful pathogens. Hygiene is crucial in today’s market, where consumers and regulatory bodies demand the highest quality standards for food products.

Conclusion

In today’s competitive meat processing industry, investing in modern cattle slaughtering machinery is essential for long-term success. The combination of automation, efficiency, and strict adherence to hygiene and animal welfare regulations ensures that businesses remain productive, cost-effective, and compliant with industry standards. Advanced cattle abattoir equipment helps streamline the slaughtering process, reduce labor costs, and produce high-quality meat products that meet consumer demands. By embracing modern technology, slaughterhouses can maintain a competitive edge while contributing to a more humane and sustainable industry.