1. Duck Stunning:

The first step in the duck slaughter process is stunning, which aims to render the birds unconscious and insensitive to pain. Modern slaughterhouses employ different stunning methods, including electrical stunning, controlled atmosphere stunning, or mechanical stunning. Electrical stunning involves the application of a mild electric current to induce unconsciousness, while controlled atmosphere stunning utilizes gas mixtures to achieve the same effect. Mechanical stunning involves the use of mechanical devices to render the ducks unconscious.

2. Duck Bleeding:

After stunning, the ducks are subjected to bleeding. This process involves the severing of the carotid arteries and jugular veins, ensuring rapid and effective blood loss. The bleeding process is crucial for both religious and practical reasons. It is essential to ensure the complete removal of blood, which can affect the meat’s quality and shelf life.

3. Duck Scalding:

Following bleeding, scalding is performed to facilitate feather removal. The ducks are immersed in hot water tanks, typically maintained at a temperature between 50-60 degrees Celsius. Scalding softens the feather follicles and allows for easier plucking, helping to maintain the integrity of the bird’s skin.

4. Duck Feather Removal:

Feather removal is accomplished through mechanical plucking machines that rotate rubber fingers or rubber discs, which gently remove the feathers. These machines operate on a conveyor belt system, ensuring a consistent and efficient plucking process. In some instances, manual feather removal may be required to achieve higher precision.

5. Evisceration:

Evisceration refers to the removal of internal organs from the duck’s body cavity. This process is performed carefully to prevent contamination of the carcass. Skilled workers use sharp knives to open the abdominal cavity and remove the organs, including the heart, liver, gizzard, and intestines. The edible organs are typically saved for further processing or sale.

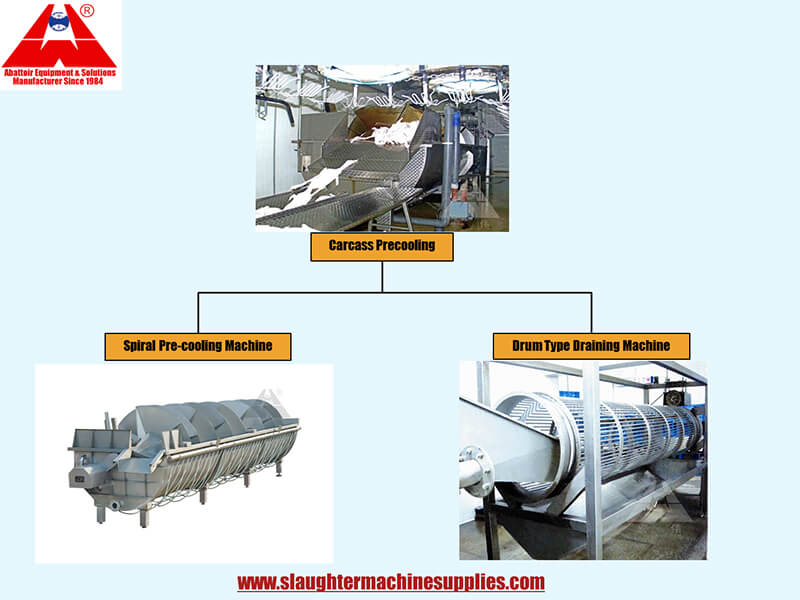

6. Duck Carcass Chilling:

Once evisceration is complete, the ducks undergo a chilling process to reduce the carcass temperature and inhibit bacterial growth. This stage may involve immersion in cold water or the use of air chilling systems. Proper chilling is crucial for maintaining the quality and safety of the meat.

7. Inspection and Grading:

After chilling, trained inspectors examine each duck carcass for any abnormalities or defects. The birds are graded based on various factors such as size, weight, fat content, and overall quality. This process ensures that only high-quality ducks proceed to the final stages of processing and packaging.

8. Further Processing and Packaging:

Duck carcasses may undergo further processing, such as portioning, deboning, marinating, or flavoring, depending on market demands and customer preferences. Processed duck products are then packaged in various formats, including whole birds, cuts, or ready-to-cook portions. Packaging is carefully carried out to maintain freshness, prevent contamination, and extend the shelf life of the products.

If you want more information, please contact us by email or WhatsApp. You can add our WhatsApp by scanning the QR code on the right.