What is Cattle & Sheep Tripe Washer?

Tripe washer is mainly used for cleaning process of pig, cattle, sheep tripe.

It is made of stainless steel and simple operation, low noise, cleanness, sanitation, etc. It can effectively improve work efficiency and reduce labor intensity of workers. It is applied to livestock slaughterhouse or abattoir.

Basic Technical Parameters of Cattle & Sheep Tripe Washer

- Production capacity: 250~280Kg/hour

- Motor: Y132M2-6-5.5kW

- Size: 1500×950×1300mm

- Weight: 500kg

Structure & Working principle of Cattle & Sheep Tripe Washer

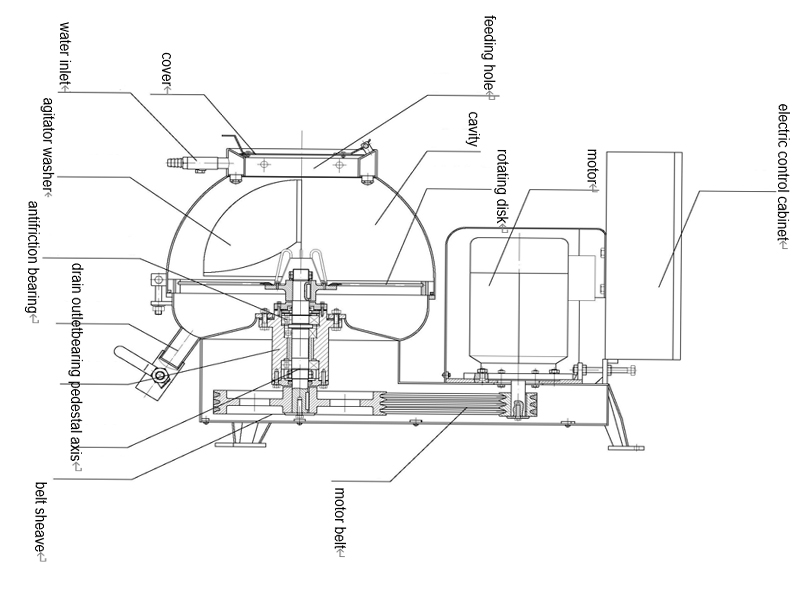

Composition structure:

- Including water inlet, drain outlet,cavity, rotating disk,axis,axis set,bearing pack, driving belt,belt sheave,motor and electric control cabinet.

Working Principle:

- The main shaft and the rotating disk are driven by the motor through a belt pulley At the same time, the pig (cow or sheep) abdomen on the rotating disk is thrown to the edge of the ball cavity under the centrifugal force, and collides with the turning block on the wall of the ball cavity.

- The backward rotating turntable causes friction between the round wheel and the round steel on the rotating disk.

- Thus, the pig (cow, sheep) belly is repeatedly cleaned and rubbed in order to complete the cleaning.

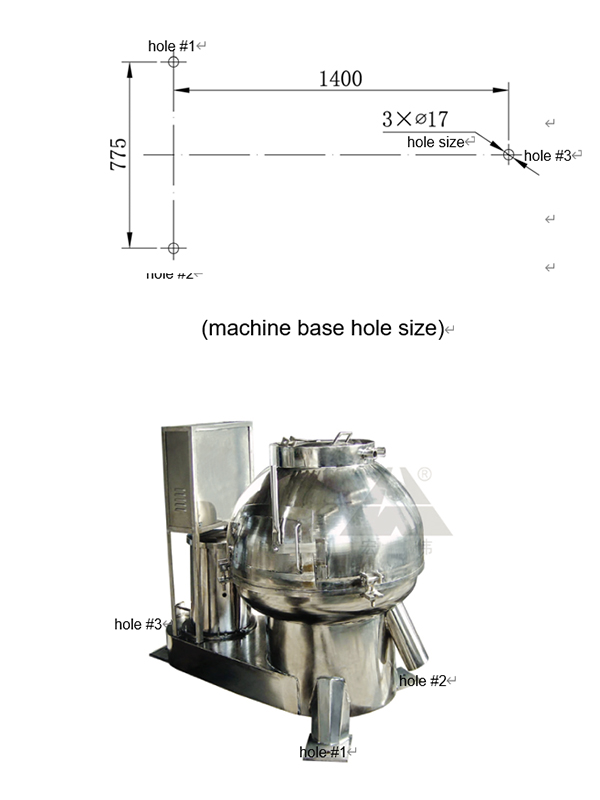

Foundation Location of Cattle & Sheep Tripe Washer

- According to onsite conditions, determine the equipment orientation.

- Refer to the diagram below for coagulation

- The soil foundation is embedded in the anchor bolt or steel plate (the bottom plate is welded and positioned) and adjust location.

Operation and Attention of Cattle & Sheep Tripe Washer

- 1.Connect the water inlet pipe with upper soft tube,

and then put into the hot and cold water

and mix water temperature to proper temperature. - 2.Put the pig (cow, sheep) tripe from the top feed port

into the ball cavity and cover it

press the motor button to start washing the belly. - 3.After cleaning process completed.

Turn off the electricity, open the drain valve to drain the sewage - 4.Take out the tripe.

Maintainence of Cattle & Sheep Tripe Washer

- 1.After work, flush the cavity inside promptly with water, cleaning dirt.

- 2.Add grease onto axis bearing every six months,if any bearing ball abrasion or loose fit, replace bearing in time.

- 3.Check the tightness of the belt regularly, to ensure the effectiveness of driving.

Structure Diagram of Cattle & Sheep Tripe Washer

Click here to learn how modern sheep slaughterhouse works..

Click here to watch how modern cattle beef slaughter line works.

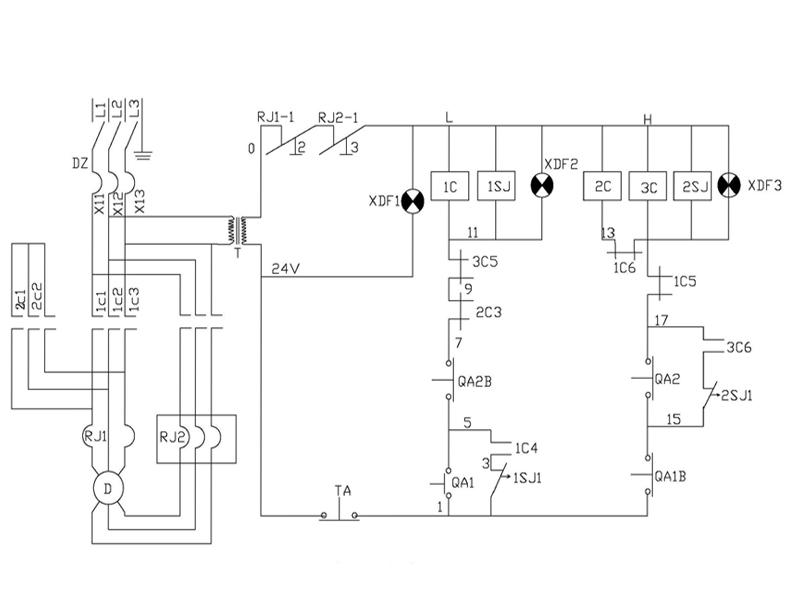

Electric Schematic Diagram of Cattle & Sheep Tripe Washer

Established in 1984, we provide turnkey abattoir solutions for cattle halal slaughter line including the slaughterhouse design, all the slaughtering equipment, slaughter and meat processing machine and accessories, installation and training. We also supply complete slaughterhouse solutions for livestock, horse, sheep or goat, and pig or hog, and poultry chicken or broiler and rabbit.